SOLAR PV PANNELS-JINKO

About Jinko Solar

Jinko Solar Co., Ltd. (the “Company”, or “Jinko Solar”) (SSE: 688223) is one of the most famous and innovative solar technology companies in the world. Its business covers the core links of the photovoltaic industry chain, focusing on the R&D of integrated photovoltaic products and integrated clean energy solutions. At present, Jinko Solar’s products serve more than 3,000 customers in more than 160 countries around the world, and the company has ranked No.1 in global module shipments for many years. By the end of March 2022, the cumulative module shipments of Jinko Solar have exceeded 100GW. Jinko Solar is an industry opinion leader under various international frameworks such as B20, and it is also the first solar energy company to join the RE100 green initiative.

Jinko Solar is the first company to establish a “vertically integrated” production capacity from silicon material processing to wafer, cell and module production in the industry. It has a total of 12 global production bases in China, the United States, Malaysia and Vietnam. By the end of 2021, the company’s effective production capacity of monocrystalline silicon wafers, cells and modules reach 32.5GW, 24GW and 45GW respectively. Jinko Solar has more than 1,000 R&D and technical employees and has won many honors such as “National Enterprise Technology Center”, “National Technology Innovation Demonstration Enterprise”, “Champion of Manufacturing “, and has formulated many international and domestic industry standards such as IEC. Jinko Solar continuously expands the diversified application scenarios of photovoltaic technology, including building-integrated photovoltaic, photovoltaic hydrogen production, energy storage and other fields, and strives to create a new energy ecosystem.

Jinko Solar was listed on the STAR Board of the Shanghai Stock Exchange in 2022, and JinkoSolar Holding Co., Ltd., its indirect controlling shareholder, was listed on the New York Stock Exchange in 2010.

Quality Tested Represents

- 52 steps quality control and inspection process

- Continuous line monitoring and video/photo records for each cell and panelThe most advanced quality assurance devices

Comprehensive QC information management system in place to allow quality data flow constantly

- Intelligent alarm and stop mechanism in case of any deviation or errors

- Stringent acceptance criteria and the tightest tolerance levels

- A team of 1500 quality control professionals

- “Zero” defects objective

Advantages for customers

- Dependable system performance due to comprehensive approval certification.

- High yields over the long run and high investment security due to stringent reliability and safety tests.

- Increased bankability due to independent certification by an internationally recognized testing and certification authority.

- Strong power generation in a given time and space because of the high efficiency of the solar cells.

- Consistent performance and durability after exposure to intense sunlight and in extreme conditions.

- Less O&M is needed due to the quality of materials used.

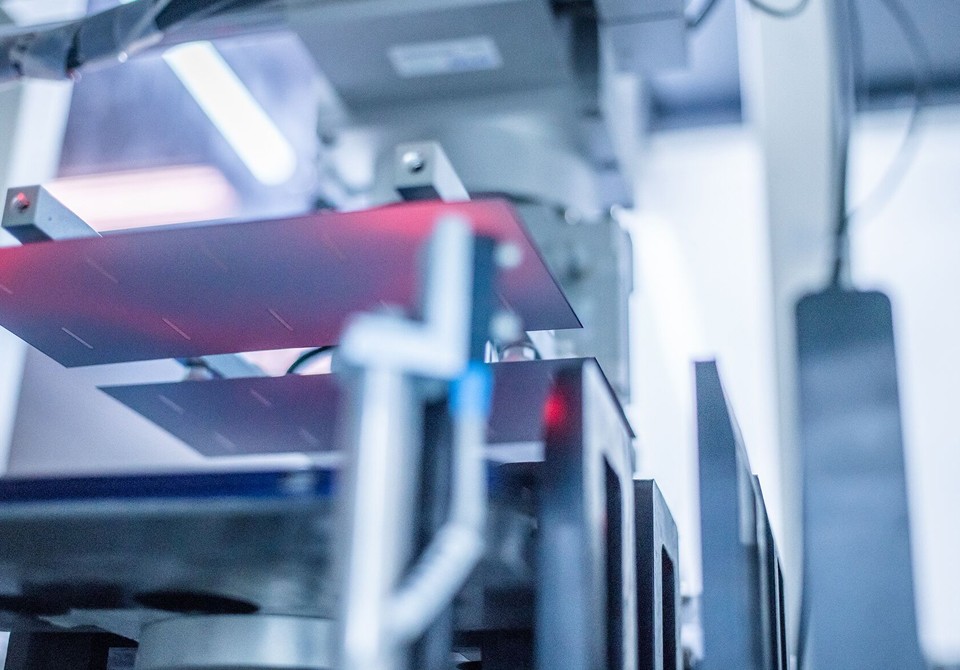

Jinko smart factory

- JinkoSolar’s smart factory quality team makes use of automated checking and analysis devices and is bringing quality management into a new era. The traditional manual inspection is partially supplemented by specialised measurement instruments. Whereas previously just a manual check allowed the desired premium quality to be verified. Today, photometric robots with extremely precise optical sensors can now carry out the required steps. In addition to the functional criteria, the optical measurement devices also focus on visual properties. All components are inspected for micro cracks, hot spot and other surface defects. The QC robots lends its attention to even the finest of details, every little shortcoming is discussed to achieve the best quality. The length of time required to complete measurement is reduced significantly.

What’s more, it does not just measure individual points; rather it precisely measures the entire surface area. Subsequently, the resulting data derived from this process is then recorded, documented, and shared within the organization simultaneously. Correction data is created if any deviation occurs, and can be used to optimize components at an early phase.

[products columns=”4″ orderby=”title” order=”ASC” ids=”3300″]